Product

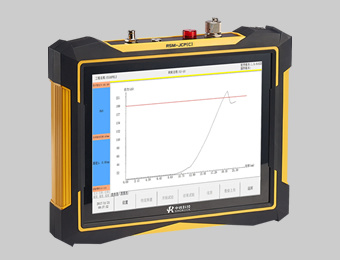

RSM-JCP(C) Bridge Tension Stress Tester

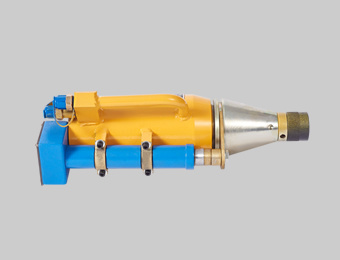

Lightweight high-pressure integrated pump, highly efficient, adaptable to complex working conditions.

Classification:

RSM-JCP(C) Bridge Tension Stress Tester integrates advanced intelligent control with a high-pressure micro pump, enabling accurate and automated effective prestress testing in post-tensioning structures. Lightweight, portable, and safe, it ensures precise results in varied construction environments.

Cotnact:

Introduction

The RSM-JCP(C) Bridge Tension Stress Tester is a professional solution developed by Sinorock for post-tensioning prestressed construction. It adopts the reverse tension method to measure effective prestress under anchors, combining an intelligent industrial-grade control system, lightweight high-pressure integrated pump, and guided operation interface. The system features automatic load control, intelligent phase-based stress management, and dual safety protection values, ensuring reliability even in harsh or complex site conditions. With lithium battery power supply and multiple power options, it is suitable for both urban projects and remote construction environments. Real-time monitoring and cloud upload enable intelligent data management and seamless reporting.

Applications

Effective prestress testing under single-strand anchors

Non-uniformity detection within a tendon group

Non-uniformity detection across the same section

Applicable standards

Technical Code for Testing Effective Prestress under Highway Bridge Anchors (T/CECS G:J51-01-2020)

Technical Specifications for Highway Bridge and Culvert Construction (JTG/T F50-2011)

Code for Quality Inspection and Acceptance of Prestressing and Cable Force Tensioning in Bridge Construction (CQJTG/T F81-2009)

Core advantages

Intelligent Control System

Smart multi-stage pressure control with automatic reverse stress termination judgment.

Compact High-pressure Micro Pump

Integrated pump with 70MPa capacity, ≤28kg full oil weight, portable and efficient, powered by lithium battery for remote projects.

High Automation

Fully automatic directional control, enabling automated load maintenance, pressure increase, and stress termination.

Enhanced Safety

Dual protection by setting initial stress, design control stress, and warning limits for safe staged pressurization.

Adaptability to Harsh Environments

Powered by 60V lithium battery or AC adapter, suitable for varied field conditions without dependence on local power supply.

Cloud-enabled Smart Testing

Real-time monitoring with wireless data upload, enabling intelligent cloud detection and reporting.

Technical Parameter

|

Model |

RSM-JCP(C) |

|

Main Unit |

|

|

Control System |

Low-power embedded system |

|

Display Mode |

12.1-inch high-brightness true-color LCD, resolution 1024×768 |

|

Communication Mode |

Wireless / Wired |

|

Wireless Range |

≥30 m |

|

Power Supply |

Removable lithium battery; can also be charged through the DC 12V digital control box |

|

Operation Mode |

Touch screen |

|

Dimensions |

340×270×73 mm |

|

Digital Hydraulic System (Single-Strand) |

|

|

Displacement Testing Channels |

2 channels |

|

Load Testing Channels |

1 pressure channel / 1 force sensor channel |

|

Displacement Measurement Accuracy |

Measurement error ≤0.1% F·S |

|

Load Measurement Accuracy |

≤0.5 grade |

|

Single-Strand Pressure Range |

0–250 kN |

|

Working Flow Rate |

Adjustable; maximum flow ≤0.18 L/min |

|

Working Voltage |

60 V DC |

|

Dimensions |

420×180×400 mm |

|

Special Jack (Single-Strand) |

|

|

Type |

Front-clamp type limiting jack |

|

Nominal Tension Capacity |

270 kN |

|

Nominal Oil Pressure |

57 MPa |

|

Center Hole Diameter |

φ19 mm |

|

Maximum Tension Stroke |

100 mm (other stroke options available) |

|

Dimensions |

φ114 × 410 mm |

|

Model |

RSM-JCP(C) |

|

Main Unit |

|

|

Control System |

Low-power embedded system |

|

Display Mode |

12.1-inch high-brightness true-color LCD, resolution 1024×768 |

|

Communication Mode |

Wireless / Wired |

|

Wireless Range |

≥30 m |

|

Power Supply |

Removable lithium battery; can also be charged through the DC 12V digital control box |

|

Operation Mode |

Touch screen |

|

Dimensions |

340×270×73 mm |

|

Digital Hydraulic System (Single-Strand) |

|

|

Displacement Testing Channels |

2 channels |

|

Load Testing Channels |

1 pressure channel / 1 force sensor channel |

|

Displacement Measurement Accuracy |

Measurement error ≤0.1% F·S |

|

Load Measurement Accuracy |

≤0.5 grade |

|

Single-Strand Pressure Range |

0–250 kN |

|

Working Flow Rate |

Adjustable; maximum flow ≤0.18 L/min |

|

Working Voltage |

60 V DC |

|

Dimensions |

420×180×400 mm |

|

Special Jack (Single-Strand) |

|

|

Type |

Front-clamp type limiting jack |

|

Nominal Tension Capacity |

270 kN |

|

Nominal Oil Pressure |

57 MPa |

|

Center Hole Diameter |

φ19 mm |

|

Maximum Tension Stroke |

100 mm (other stroke options available) |

|

Dimensions |

φ114 × 410 mm |

Standard Configuration

Prestressing Stress Tester 1pc

DC Control Box 1pc

Miniature DC Pump 1set

Special Jack 1 set

Control Box Communication Cable 1pc

Pressure Sensor 1pc

Pressure Sensor Connection Cable 1pc

Sucker antenna 3pcs

Quick Connector 1 set

Lithium Battery Charger 1pc

Lithium Battery 1pc

Tee Connector 1pc

Hydraulic Hose Assembly 1set

Jack Displacement Connection Cable 1pc

Toolkit 1 set

Power adapter 1pc

Instrument container 1pc

Market Case

Downloads

FAQs

Q

What does the RSM-JCP(C) test and what method does it use?

+

A

It measures effective prestress under anchors in post-tensioned bridge structures using the reverse tension method. Typical uses include checking effective prestress under single-strand anchors and detecting non-uniformity within a tendon group or at the same section. It references standards such as T/CECS G:J51-01-2020, JTG/T F50-2011, and CQJTG/T F81-2009.

Q

How does it improve on-site safety and automation?

+

A

The system provides automatic load control, intelligent multi-stage pressure management, and dual safety protection values (initial stress, design control stress, warning limits) for safe staged pressurization—even in harsh conditions. Real-time monitoring plus wireless data upload support cloud-enabled reporting and management.

Q

Is it portable, and what are the key hardware specs?

+

A

Yes. It combines a lightweight high-pressure micro pump (up to 70 MPa, full-oil weight ≤28 kg, 60 V DC lithium battery/AC power) with a 12.1″ high-brightness LCD host (wireless/wired, ≥30 m wireless range). The single-strand hydraulic unit offers 2 displacement channels, 1 pressure/1 force channel, displacement error ≤0.1% FS, load accuracy ≤0.5 grade, 0–250 kN pressure range; the special jack is front-clamp type, 270 kN nominal tension, 57 MPa nominal oil pressure, φ19 mm center hole, 100 mm max stroke.

Previous Page

Next Page