Product

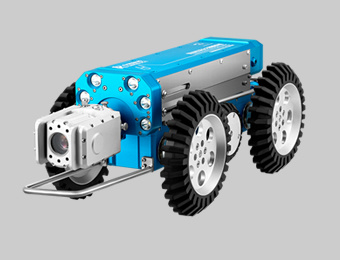

RSM-RTV (E) Pipeline Crawler

Dual HD Vision · Rugged & Intelligent · 360° Pipeline Insight

Classification:

Dual HD cameras, rugged build, and full-scene visibility — RSM-RTV(E) is a next-generation pipeline inspection robot engineered for accurate, efficient, and real-time structural assessment of pipelines.

Cotnact:

Introduction

The RSM-RTV(E) Pipeline Crawler features a modular system composed of a crawler, control unit, motorized cable reel, and high-definition front/rear cameras. Operators can control the crawler via tablet interface, enabling full 360° real-time visual inspection of both structural and functional pipeline defects.

The crawler is equipped with a dual X-type gimbal for enhanced stability and durability. A front anti-collision bumper and reinforced camera housing further improve robustness in challenging environments. The system integrates high-definition digital imaging, high-torque DC motors, GPS positioning, and a lightweight automatic cable reel to ensure clear imaging, stable performance, and efficient on-site operations.

It supports synchronized video recording and defect marking during inspection and allows instant report generation—delivering valuable data for pipeline maintenance planning and repair decision-making.

Application

Municipal (Industrial) drainage pipelines, water conservancy and water transmission pipe culvert, utility tunnel, cable trench and tunnel.

Applicable standards

Technical Code for Inspection and Evaluation of Urban Drainage Pipelines (CJJ 181-2012)

Technical Code for CCTV and Sonar Inspection and Evaluation of Drainage Pipelines (DB31/T 444-2022)

Technical Code for Inspection and Evaluation of Urban Public Drainage Pipelines (DB44/T 1025-2012)

Standard for Functional Classification of Drainage Pipelines and Conduits (Q/BDG JS001-GW05-2012)

Standard for Functional Classification of Drainage Pipelines and Conduits (Q/BDG JS002-GW05-2012)

Core advantages

Dual HD Imaging, Clear & Precise

Equipped with front and rear digital HD cameras for comprehensive visual coverage

High-brightness LED composite lighting ensures sufficient illumination in dark pipeline interiors

Rear-view camera with elevating mechanism for wider observation angles

Rugged Protection Design

Front anti-collision bumper and reinforced camera housing to prevent damage

Dual X-type gimbal structure provides enhanced durability and impact resistance

Flexible Control & Efficient Detection

Supports laptop or tablet control, with easy device switching

Gigabit wireless router with dual antennas ensures fast and stable signal transmission

Real-time video recording and defect tagging with instant report output during inspection

Powerful Performance, Unstoppable Drive

Driven by high-torque DC motors

Six-wheel independent drive on both sides enables obstacle crossing and 360° in-place rotation

Maximum climbing capability up to 45°

Compact & Maintainable Design

Lighter, detachable cable reel base easily fits in a car trunk

Modular design reduces failure rate and simplifies maintenance

Enhanced traction system with maximum pulling force up to 14 kg

Technical Parameter

RSM-RTV(E) Technical Specification

|

Parameter |

Specification |

|

Dimensions |

696 × 268 × 240 mm (with 8-inch wheels) |

|

Weight |

22 kg |

|

Operating Temperature |

-10℃ to +50℃ (non-freezing conditions) |

|

Applicable Pipe Size |

Suitable for pipelines with diameter ≥ 300 mm |

|

Communication |

Compatible with both wired and wireless modes |

|

Protection Level |

IP68 – Dustproof and waterproof |

|

Lighting |

Front: 6×10W spotlight LEDs + 4×5W flood LEDs |

|

Obstacle-Crossing Ability |

Climb 45° slope, cross 10 cm step, load capacity ≥ 80 kg |

|

Single Travel Distance |

Standard 120 m cable (custom lengths available) |

|

Travel Speed |

Up to 34 m/min |

|

Lateral Tilt Resistance |

Up to 45° |

|

Wheels |

6-wheel dual drive system, supports in-place rotation |

Camera Gimbal

|

Parameter |

Specification |

|

Rotation / Reset |

360° axial rotation, 180° tilt, one-click auto-reset |

|

Camera Resolution |

Front: 5 MP / Rear: 3 MP |

|

Focus / Zoom |

Autofocus + manual adjustment; 10× optical zoom |

|

Lifting Height |

0–180 mm (excluding crawler height) |

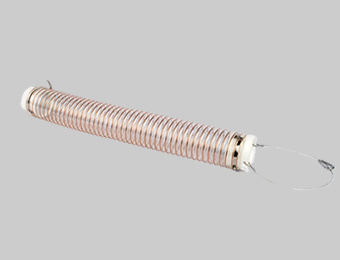

Cable Reel

|

Parameter |

Specification |

|

Dimensions / Weight |

585 × 389 × 452 mm (including 120 mm chassis height) |

|

Cable |

2-core, 8 mm outer diameter, 300 kg tensile strength |

|

Length Counting |

High-precision encoder, accuracy ±0.1 mm |

|

Cable Management |

Motor-driven automatic retraction, jog control supported, brake tension adjustable, emergency stop button included |

|

Mobility |

Two fixed wheels + two universal wheels with brakes |

|

Power Supply |

AC/DC compatible |

|

Max Pulling Force |

Up to 14 kg |

|

Cable Winding |

Multi-layer automatic winding |

Control Terminal

|

Parameter |

Specification |

|

Devices Supported |

Laptop, tablet, smartphone |

|

Information Display |

Real-time video, date/time, crawler status, speed, travel distance, GPS location; supports video headers and custom text overlays |

|

Control Functions |

- Pan/tilt and zoom control of camera |

Standard Configuration

Main Control Terminal 1 set

Automatic Cable Reel (Electric) 1 set

Crawler Vehicle 1 set

Downhole Sleeve 1pc

Downhole Hook 1pc

Wellhead Pulley Frame 1pc

6-inch Solid Tires 4pcs

4-inch Solid Tires 4pcs

Air Pump 1pc

Power Cable 1pc

Wrench 1pc

Manual Winding Handle 1pc

Safety Ropes 2pcs

Crawler Flight Case 1pc

Tool Kit Quantity: 1 set (Contents: USB drive, Allen wrench set, lubricant, assorted screws)

Anti-collision Rod 1pc

Rain Repellent 1pc

Portable AC/DC Power Supply 1pc

Special Tool Kit 1pc

Market Case

FAQs

Q

Q1: What is the minimum pipe diameter supported by the RSM-RTV(E) robot?

+

A

A: The RSM-RTV(E) is suitable for inspecting underground pipelines with a diameter of 300 mm or greater, making it ideal for a wide range of municipal and industrial applications.

Q

Q2: Is the robot capable of operating in harsh or wet environments?

+

A

A: Yes. The crawler unit is IP68-rated, providing full dust and water protection. It also features a rugged chassis, anti-collision design, and wide temperature tolerance from -10°C to 50°C.

Q

Q3: Can the system perform real-time defect marking and generate inspection reports on site?

+

A

A: Absolutely. The system supports simultaneous video recording and defect annotation, and can automatically generate inspection reports during the detection process—enabling efficient, on-site documentation.

Q

Q4: How is the robot controlled, and what devices are supported?

+

A

A: The RSM-RTV(E) can be controlled via laptop, tablet, or smartphone, supporting both Windows and Android platforms. The control software displays real-time video, positioning, travel status, and allows full control over camera movement, zoom, lighting, and data capture.

Previous Page

Next Page

Keyword:

RSM-RTV (E) Pipeline Crawler